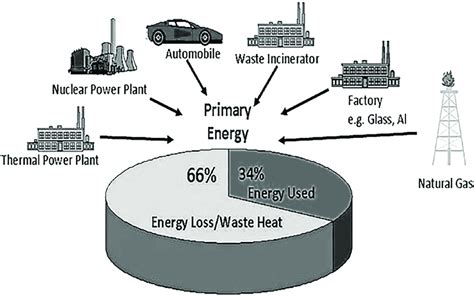

Waste heat energy, a byproduct of industrial processes, presents a significant opportunity for power generation and energy efficiency improvement. The concept of harnessing waste heat for electricity production has been around for decades, but advancements in technology have made it more viable and efficient. In various sectors, including chemical processing, oil and gas, and manufacturing, waste heat recovery systems can significantly reduce energy consumption and greenhouse gas emissions. This article delves into the principles, technologies, and benefits of waste heat energy power generation solutions, highlighting their potential to transform industrial energy management.

Key Points

- Waste heat recovery systems can improve industrial energy efficiency by up to 30%.

- Organic Rankine Cycle (ORC) systems are a popular choice for waste heat power generation due to their flexibility and efficiency.

- Heat exchangers play a critical role in waste heat recovery, with materials like stainless steel and titanium offering high durability and resistance to corrosion.

- Kalina Cycle systems offer higher efficiency than traditional Rankine cycles, especially in applications with low-temperature waste heat.

- Implementing waste heat power generation can lead to significant reductions in CO2 emissions, contributing to a more sustainable industrial sector.

Principles of Waste Heat Recovery

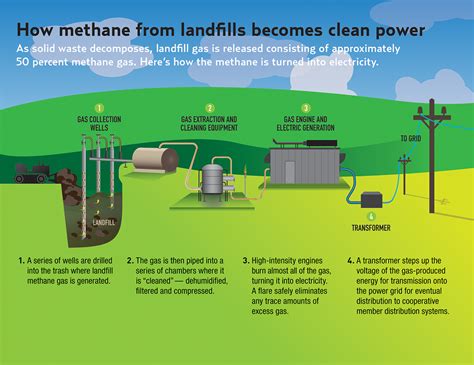

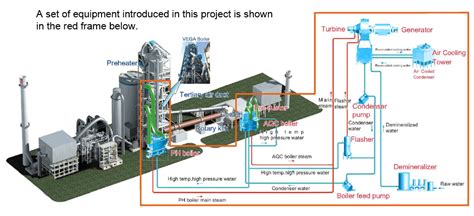

The principle behind waste heat recovery for power generation is to capture the thermal energy that would otherwise be lost and convert it into electricity. This process involves several key steps: heat collection, heat transfer, and power conversion. Heat exchangers are used to collect waste heat from various sources, such as exhaust gases or cooling systems, and transfer it to a working fluid. This fluid then drives a turbine or an engine to generate electricity. Understanding the temperature and flow rate of the waste heat stream is crucial for designing an efficient recovery system.

Technologies for Waste Heat Power Generation

Several technologies are employed for waste heat power generation, each with its advantages and suitable applications. The Organic Rankine Cycle (ORC) is widely used due to its ability to operate efficiently at lower temperatures, making it suitable for a broad range of industrial waste heat sources. Another technology is the Kalina Cycle, which offers higher efficiency than traditional Rankine cycles, especially in applications with low-temperature waste heat. Additionally, steam Rankine cycles are used for higher temperature waste heat sources, providing a more conventional approach to power generation.

| Technology | Efficiency Range | Suitable Temperature Range |

|---|---|---|

| Organic Rankine Cycle (ORC) | 10-20% | 80°C - 350°C |

| Kalina Cycle | 15-25% | 70°C - 300°C |

| Steam Rankine Cycle | 20-30% | 150°C - 550°C |

Benefits and Challenges of Waste Heat Power Generation

The benefits of waste heat power generation are multifaceted, including improved energy efficiency, reduced greenhouse gas emissions, and enhanced profitability for industries through the generation of electricity from previously wasted energy. However, there are also challenges to consider, such as the high initial investment costs, the need for careful system design to match the waste heat source characteristics, and the potential for corrosion and maintenance issues in heat exchangers.

Case Studies and Real-World Applications

Several industries have successfully implemented waste heat recovery systems to generate power. For example, in the cement industry, waste heat from kilns can be used to produce electricity, reducing the plant’s energy consumption and emissions. Similarly, in the oil and gas sector, waste heat from processes like gas compression and pipeline transmission can be harnessed for power generation. These real-world applications demonstrate the feasibility and benefits of waste heat energy power generation solutions.

What are the primary challenges in implementing waste heat recovery systems?

+The primary challenges include high initial investment costs, the need for customized system design, and potential operational issues such as corrosion and maintenance of heat exchangers.

How does the efficiency of waste heat recovery systems impact their viability?

+The efficiency of waste heat recovery systems directly affects their economic viability. Higher efficiency systems can generate more electricity from the same amount of waste heat, making them more attractive from an economic and environmental standpoint.

What role do policies and regulations play in the adoption of waste heat power generation technologies?

+Policies and regulations can significantly influence the adoption of waste heat power generation technologies by providing incentives, setting standards for energy efficiency, and facilitating the integration of these systems into existing energy infrastructure.

In conclusion, waste heat energy power generation solutions offer a promising approach to improving energy efficiency, reducing emissions, and generating additional power from industrial processes. As technology continues to evolve, the efficiency and cost-effectiveness of these systems are likely to improve, making them an increasingly viable option for industries seeking to reduce their environmental footprint and enhance their energy management practices.